Safety

ENVIRONMENTAL HEALTH AND SAFETY

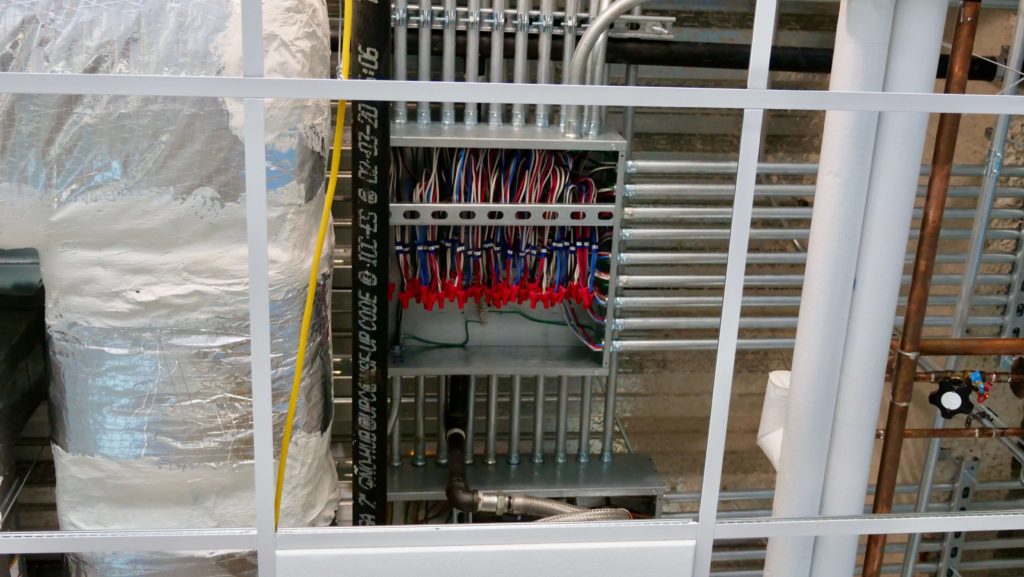

At All Phase Electric and Maintenance, we are proud of our commitment to the health and safety of our staff and customers. From routine employee drug testing to comprehensive site and job-specific safety practices, we are dedicated to preparing for, identifying, and mitigating every type of risk that may come up on our projects.

Our Safety Director works hand-in-hand with Project Managers and Foremen to ensure that safety is emphasized at all times and on all projects. This includes pre-employment drug testing, random employee drug testing, weekly safety meetings, and extensive reviews of safety precautions with pre-tasks specifically relating to hazardous operation

ANNUAL SAFETY AUDIT

Our Safety Training and Company Safety Programs are reviewed on an annual basis by certified third-party safety auditors. All potential areas of risk are addressed, including but not limited to:

- Respiratory protection

- Fall protection

- Fire extinguisher use

- Fire safety/prevention

- Back injury prevention

- Lifting techniques

- Procedures for energizing and de-energizing circuits

- Lock out tag out

- Excavations/trenching

- Power equipment operations

- Aerial lift operation

- Forklift operation

- Scaffolding and ladder safety

- Hearing protection

- Arc flash protection

- Basic first aid

- CPR/AED

- Asbestos management for maintenance workers

- Blood borne pathogens

- Confined space entry

- Rigging/material handling

- HazCom/MSDS

- Hand tool use

- Housekeeping

- General safety rules

- What to do in case of accidents

- Accident investigation

OSHA STANDARDS

In addition to those areas listed above, we strictly enforce OSHA Electrical Industry standards for 29 CFR 1926, 1910 and utilize NFPA 70E for electrical safety, Arc Flash protection, and shock protection boundaries for both qualified and unqualified workers. This ensures the safety of our customers and their employees, as well as our own electricians on the job.